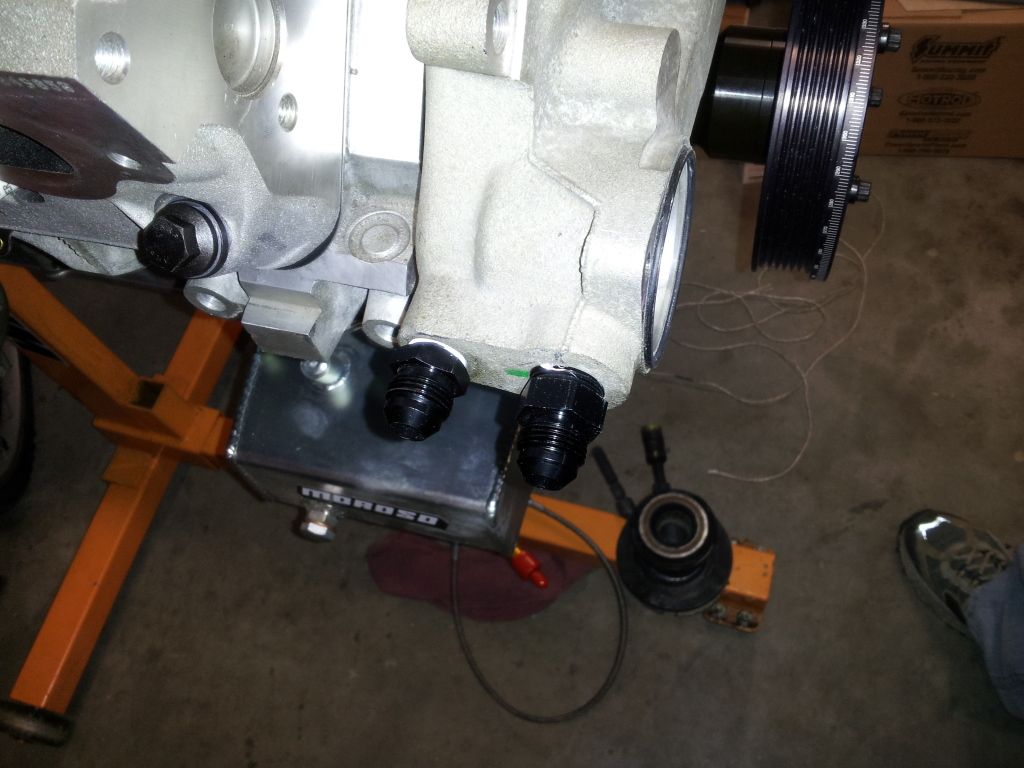

The McLeod Mag Force Twin is a seriously beautiful piece, its really sad that it has to be buried behind a bellhousing. I bought it to run it though so it has to go in. This being a twin its a little different from other clutch installations I have experienced.

First you pop off the pressure plate to see the ceramic pucked solid hub disc that's backed up by a floating pin drive center disc. I chose the floating center disc based on recommendations that it would drag less as the clutch begins to wear, allowing me a slightly longer interval for re-shimming the clutch.

On top of the drive pins there are shim stacks calibrated from the factory for proper finger height on the clutch diaphragm. As the clutch wears, shims will be removed until either one of the plates are out of spec or the clutch is worn or damaged to the point where it needs to go back to McLeod for a full rebuild.

I have the strapped pressure plate to keep some of the noise down.

I'm using ARP pro series 12pt flywheel bolts to protect the investment p/n 330-2802

Using the standard clutch alignment tool this is all the further the transmission would engage, I thought I could get away with it, but I no matter what I tried I couldn't get it any closer than the last inch. Finally I broke down and bought the Quarter Master 1-5/32" x 26 spline alignment tool. Its under $50 and well worth it to just go ahead and get it if you're going to install a multi-plate clutch.