|

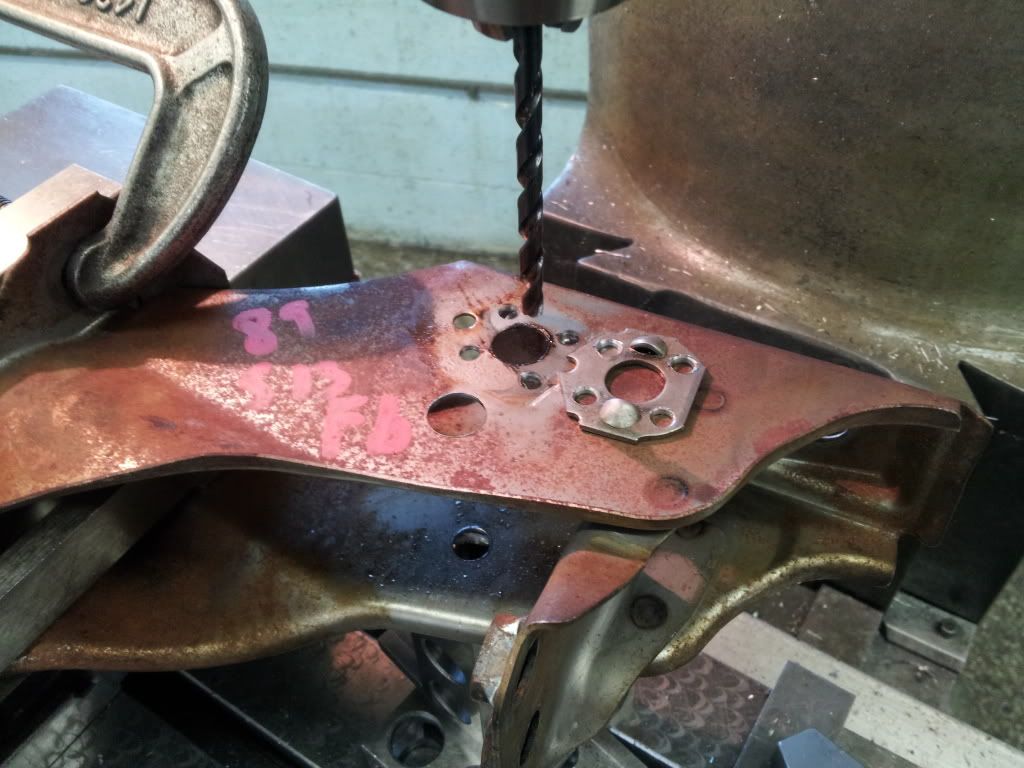

| Made two of the master cylinder adapter plates in the CNC with some assistance, it was pretty exciting to push that green button after the program was made. |

|

| Facing my new brake pedal pivot to length in the lathe. |

|

| Brake pedal with a new pivot added 1" below the factory pivot |

|

| We added another hole in the brake bracket as well to keep the same pedal height, keeping the brake push rod going out the same hole in the firewall. |

|

| My super fancy brake push rod. I might make something a little prettier without the length adjustment after some testing. |

For the brake lines I ran all new. I chose NiCopp for the corrosion resistance and formability. NiCopp lines are supposed to combine the corrosion resistance of stainless with easier forming than mild steel. Its a Nickel, Copper alloy, and somehow you gain resistance to fatigue and work hardening from the Nickel in the alloy over plain Copper (which is a no no in automotive braking systems). The lines in a 240 are 3/16" OD with M10 x 1.0 inverted flare fittings. The NiCopp bent surprisingly easy, I used a basic bend tool and some bend pliers for some of the tighter stuff and occasionally a 3/8 socket.

|

| I equally spaced two #10-32 rivnuts into the firewall just below the pinch seam for a nice low profile clean place to run the brake lines. |

|

| Nice, new, shiny NiCopp brake lines all bent up. |

This comment has been removed by the author.

ReplyDelete