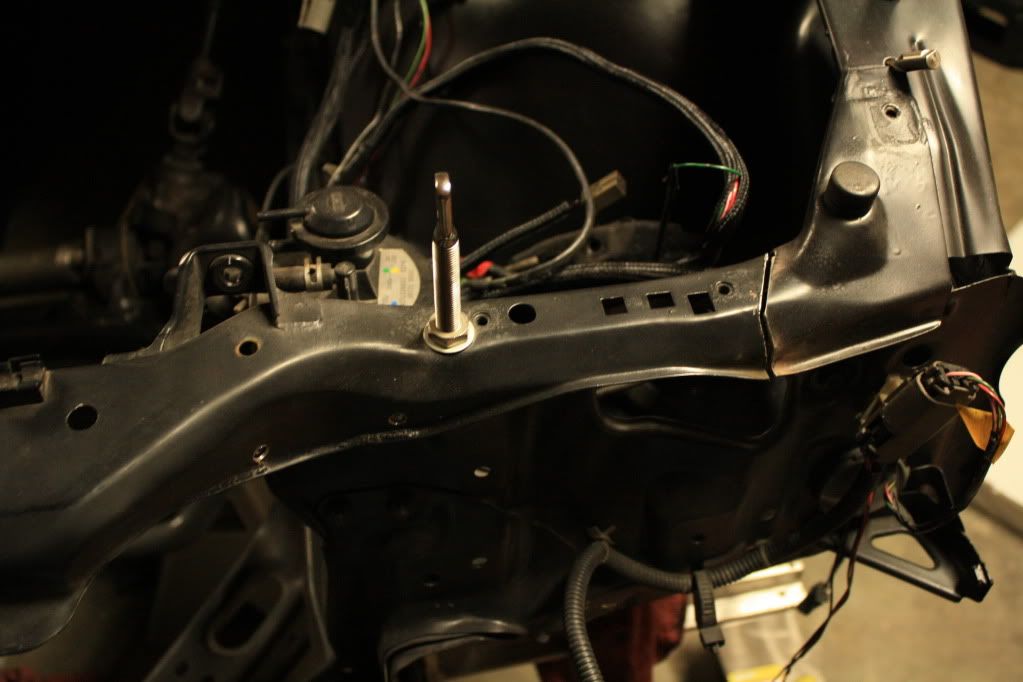

This summer I began the tear down. What started as a quick clean up job became much more.

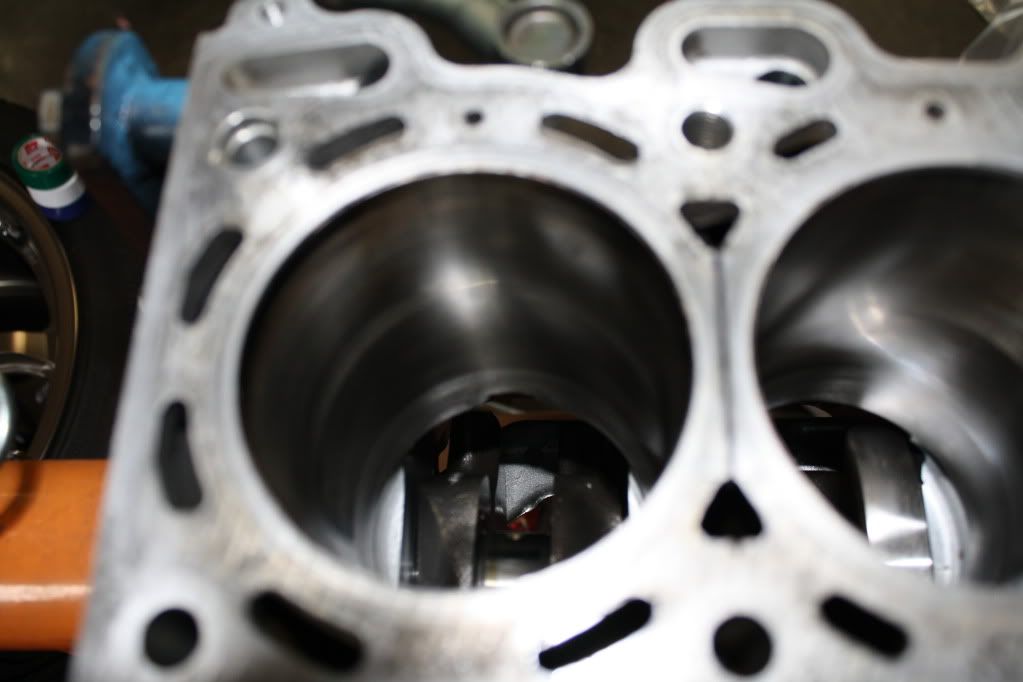

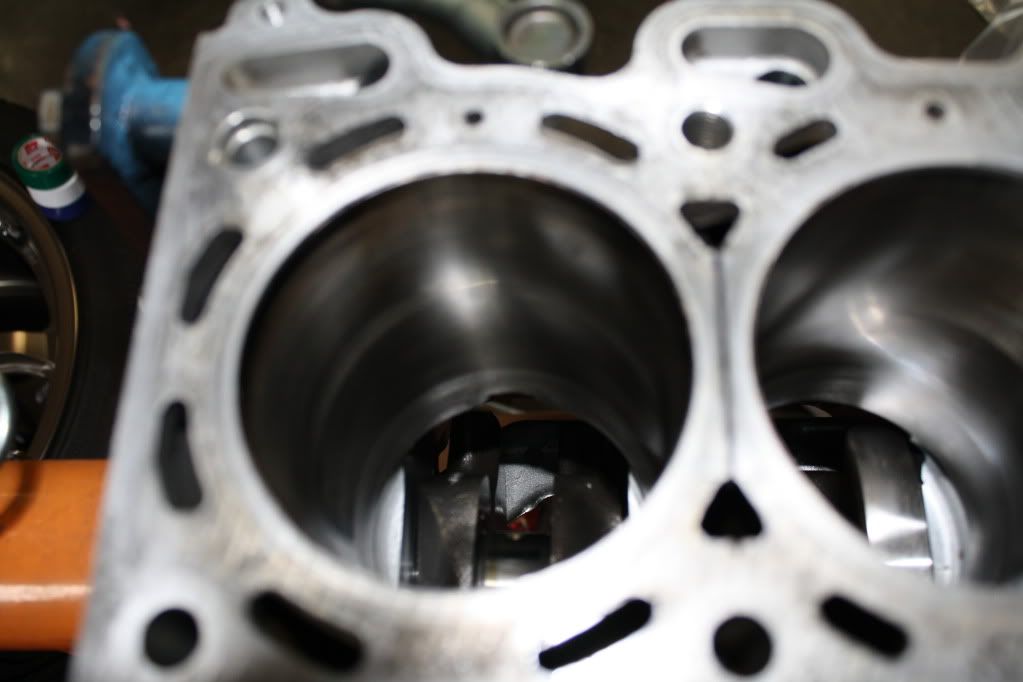

There was scoring in the cylinders, a broken section of cylinder sleeve and one SR20DE rod that didn't belong, which I'm sure was doing great things for the balanced rotating assembly. The LS1 decision caused a few sleepless nights, I loved making power with the disco potato boosted SR and the insane surge as it rushed up to 18psi. The LS just seemed like a crime against nature, so much of what I had done to the car was to make it more like the Japanese Nissan Silvia and I was going to tear its 2.0 liter turbo charged soul out, sell it all for parts and replace it with American iron....er aluminum. The decision finally just came down to logic, the car typically was spending more time apart than together, no fault of the engine itself, but I just couldn't build the same thing again, and every mod done to the car was to make more power and to keep it lower in the revs to make it more responsive. The next natural progression was to use a v8 that wouldn't have to breathe hard for my modest power goals (375-390whp)

Locating an Engine

I started with buying an engine off of Ebay from some guy in Texas. He seemed like a nice enough guy until about a month later when I was still getting excuses on where my engine was and couldn't seem to give me a straight answer on when it would ship. I called him and he claimed that he didn't have the engine or the money and that some friend of his did. Finally I had enough and luckily through paypal I was able to get my money back. Round two: I discovered Search Tempest and searched a 150 mile radius on Craigslist and found a few engines, I finally found one in Dayton. Low mileage from a 2002 WS6, with a T56, it came with the improved LS6 intake, I was happy with my find.